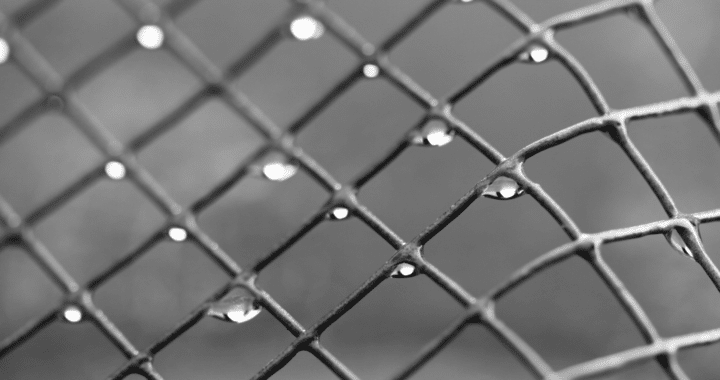

Wire mesh stands as a versatile and essential material in a wide range of industrial settings, serving various purposes beyond simply dividing spaces, adding security fences, or filtering applications. From protective barriers to safety screens, wire mesh in industrial settings play a crucial role in preventing accidents and injuries, ensuring workplace safety, and offering valuable solutions for industry-specific needs. Continue reading to find out how wire mesh can enhance industrial safety and the real-world applications it’s used in today.

Protective Barriers

Wire mesh is often utilized as a protective barrier in industrial environments to secure dangerous machinery or restrict access to hazardous areas. By acting as a physical barrier, wire mesh helps prevent accidents by keeping employees and visitors safe from potential harm. For example, in manufacturing facilities where heavy equipment is in operation, wire mesh enclosures provide a protective barrier that shields workers from moving parts, flying debris, or falling objects. In non-industrial settings, wire mesh can also be valuable in food and beverage operations and in domestic households as splatter screens and even fryer baskets.

Machine Guards

Wire mesh is also commonly used as machine guards to protect operators from coming into contact with moving parts or high-temperature surfaces. These guards are essential for ensuring worker safety around industrial equipment such as conveyor belts, robotic arms, and processing machinery. By installing wire mesh machine guards, companies can significantly reduce the risk of workplace accidents and injuries caused by contact with machinery. In high-temperature environments, wire mesh is an optimal material due to its durability and corrosion-resistant properties.

Safety Screens

Another critical application of wire mesh is in the creation of safety screens that shield workers from hazardous materials, sparks, or intense heat. In welding operations, for instance, wire mesh screens can contain sparks and molten metal splatter, preventing burns and injuries to nearby workers. Safety screens made from wire mesh are also utilized in the mining industry to protect workers from flying debris and falling rocks. In your own home, wire mesh can be used to create fireplace screens to prevent sparks from reaching your furniture or carpet.

Why Wire Mesh is a Preferred Material

Wire mesh products are known for their durability and flexibility, making them ideal for various industrial applications. They can withstand harsh conditions, such as extreme temperatures, corrosive environments, and high-impact situations, without compromising their structural integrity. Furthermore, wire mesh can be customized and tailored to specific industrial needs, whether it’s adjusting the mesh size, wire diameter, or material composition to optimize performance.

How Wire Mesh is Used in Real-Life

Wire mesh for industrial safety is used today in many factories and warehouses. Here are just a few of the real-life ways safety mesh solutions are being used to enhance industrial safety in different industries.

Automotive Industry: In automotive manufacturing plants, wire mesh partitions are installed to separate different production areas and create safe zones for workers. These partitions help prevent accidents by keeping personnel away from potentially hazardous equipment and machinery. Additionally, wire mesh is used to create many automotive parts including grills, airbag filters, and exhaust seals.

Food Processing Facilities: Wire mesh conveyor belts are widely used in food processing facilities to transport products through various stages of production. These belts are hygienic, easy to clean, and resistant to corrosion, making them essential for maintaining food safety standards. Food-grade stainless steel is the preferred wire mesh alloy for these applications.

Construction Sites: Wire mesh fencing is utilized on construction sites to establish secure perimeters and prevent unauthorized access. This type of fencing enhances safety by minimizing the risk of trespassing, theft, or accidents on the site. The benefit of using wire mesh for these types of needs lies within the materials ability to provide air flow while still allowing visibility.

Enhancing Industrial Safety with Lawrence Sintered Metals

The applications of wire mesh in industrial settings are vast and indispensable for ensuring workplace safety, preventing accidents, and enhancing productivity. The durability, versatility, and customization options of wire mesh products make them invaluable solutions for addressing specific industry needs and requirements. By incorporating wire mesh into various safety measures and equipment designs, companies can create safer, more efficient work environments that prioritize the well-being of their employees. Lawrence Sintered Metals is a trusted manufacturer of wire mesh for a variety of needs including enhanced industrial safety. We can provide industrial safety products of wire mesh in the exact mesh size, wire diameter, and material alloy you may need for your next application. If you’re interested in learning more about our wire mesh offerings, please contact Lawrence Sintered Metals.