Wire Mesh Application: Drain Filters

Metal mesh is a common item in any household or business. Lawrence Sintered Metals offers a wide variety of metal mesh and metal screens for health and safety. Some of the most common uses are stainless steel strainers, which are often used in sinks, showers, and bathtubs.

Metal mesh screen strainers help to keep gravel, deposits that break free, and other stray items in the line from going down the sink. Due to the velocity of the water pushing them, they can severely damage or clog devices installed in the flow stream of the water line, for example, p-traps or pipes.

A metal mesh strainer is essentially a screen installed to allow water to pass through, but not larger items. The larger items fall to the bottom or are held in a basket for later clean out. They normally have an access that allows them to be cleaned or have the strainer plate or basket replaced.

Metal mesh strainers come in several different styles based on the needs. The metal mesh basket strainer is easier to clean, since debris is captured in the basket. It can also sometimes offer more straining surface area than a plate strainer, improving flow rates, or decreasing pressure loss through the strainer.

Nutsche Filters and Filter Dryers for Pharmaceutical Companies

Wire mesh can be used in a variety of ways in the pharmaceutical industry. One example is using sintered wire mesh in Agitated Nutsche filters for pharmaceutical processing. However, they can also be used for paints, dyes, and wastewater treatment.

Agitated Nutsche filters work by using a vacuum or pressure in a closed system for solid-liquid separation, wherein the solids can be immediately discharged via a side discharge valve into a dryer.

The filters themselves can be made from stainless steel, Hastelloy, and mild steel. Other components can also be made of rubber or glass lining, as well as polypropylene fiber-reinforced plastic (PPFRP). Components of a Nutsche filter include a dished vessel and a perforated plate with a filter disc on the bottom, although other parts can be added depending on the use case. The filter disc can come in the form of a filter cloth, sintered wire mesh, or perforated support plate with either metallic or non-metallic filter mesh.

Another part is the agitator, which performs a number of essential functions such as maintaining a uniform cake of slurry contents to allow for easier reslurry washing and refiltration of the mother liquor. Lastly, the hydraulic power pack or power unit keeps the system running properly.

Nutsche Filters Applications and Uses

Nutsche filters are great assets in the pharmaceutical industry, or any industry that requires the handling of chemical compounds. Agitated Nutsche filter dryers allow for active chemical ingredients (ACI) or active pharmaceutical ingredients (API) and chemical compounds to filter and dry within the same unit, thus reducing their exposure.

Wire Mesh for Nutsche Filters

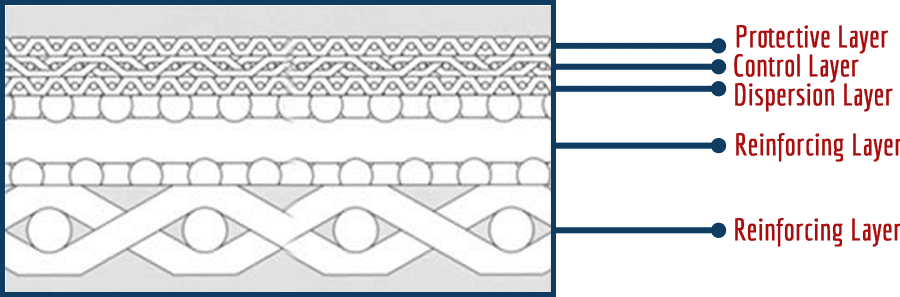

Our 5-layer sintered wire mesh laminate is ideal for use in Nutsche filters in the pharmaceutical and chemical industries. This filter medium has the ability to operate under a wide variety of temperatures and pressures while maintaining its opening size. It has excellent corrosion resistance and mechanical strength. And unlike other sintered powder filter media, it has the ability to be cleaned by backwashing.

Our 5-layer sintered wire mesh laminates are available in a wide variety of filter ratings, in 316L Stainless Steel or Hastelloy. Our standard size 24″x48″ and 48″x48″ pieces can be cut and welded together to form larger circular filters and bolted or welded in place.

Contact us today for a quote for all types of sintered wire mesh.

Sintered Wire Mesh Laminate Applications: Pleated Filters

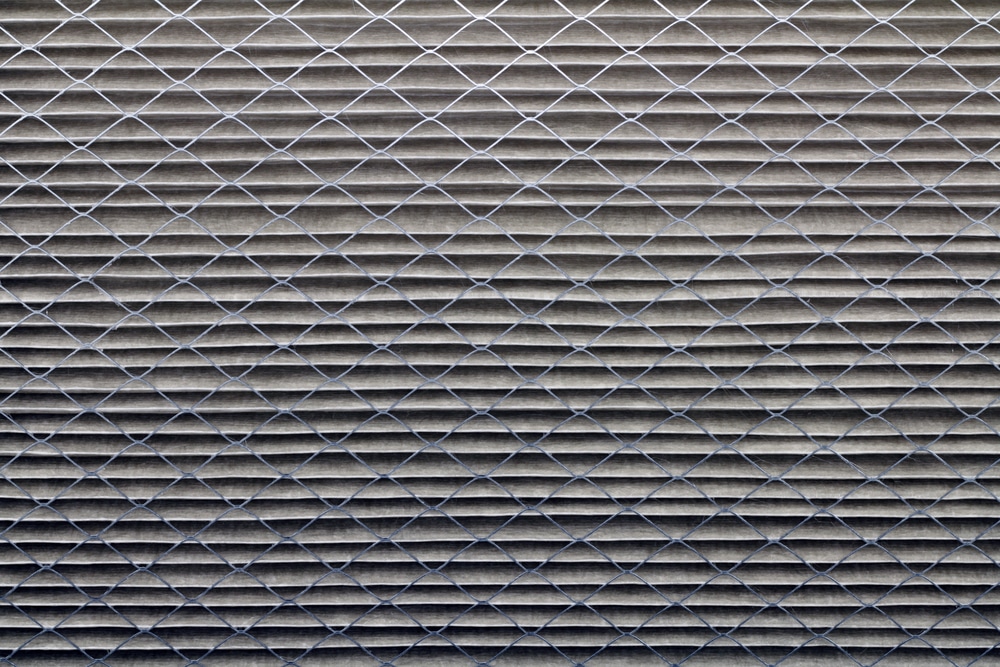

Our 3-layer sintered wire mesh laminate is ideal for use in pleated filter elements. The two coarser support layers that are used to sandwich the filter layer help to prevent closing off of pleats.

Sintering also helps the filter mesh maintain a consistent opening size through the pleating process, and helps to produce a superior pleated filter in comparison to one made conventionally with a single layer of regular wire mesh.

We can help you design a 3-layer configuration based on the filter rating you need for your pleated filters.