Sintered wire mesh is created through the process of sintering. Sintering is a process that applies heat and pressure to bond the contact points of all wires together to form a securely fused wire mesh product.

Sintered Wire Mesh Advantages

Sintered wire mesh has many advantages that make it an ideal choice for industrial applications. Advantages include:

- High mechanical strength, with the ability to maintain a steady filter rating under high pressure.

- Easy to clean with a variety of filter cleaning techniques and reuse.

- Heat and corrosion-resistant.

- Easy to fabricate, weld, punch, shear, or otherwise form into various parts.

- Wide range of filter ratings.

Lawrence Sintered Metals offers several standard types of wire mesh laminates, including options with perforated metal—all available from our U.S. stock to help you avoid import-related delays and high tariffs. Below are our sintered wire mesh products:

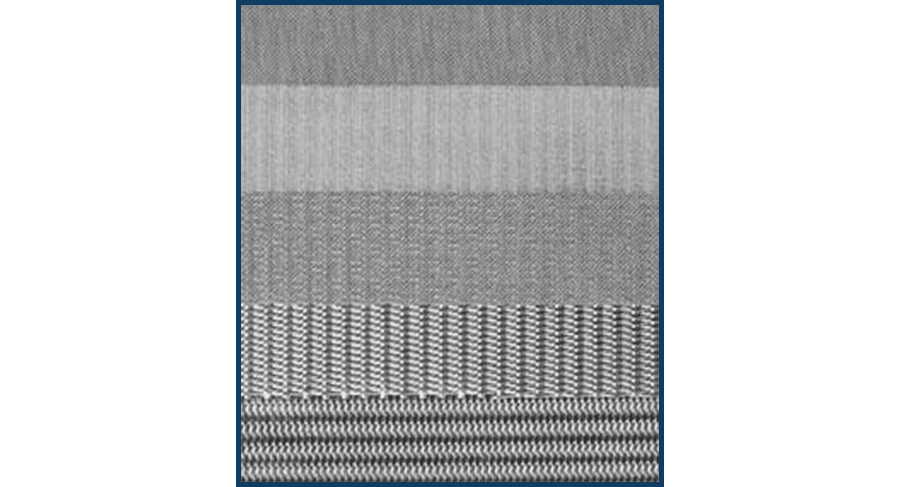

5-Layer Sintered Wire Mesh

Our 5-layer sintered wire mesh laminate is a standard and widely used type of sintered wire mesh. A single layer of fine woven wire mesh is placed between two layers of coarser square woven meshes, which are then added to two layers of a strong Dutch woven wire mesh and sintered together to form a strong plate. The single layer of fine woven wire mesh acts as the filtration layer and can be customized to meet a particular filtration rating, ranging from 1 micron to 200 microns. The layers used to create 5-layer sintered wire mesh generally consist of 316L stainless steel but can be customized using a variety of alloys.

Sintered Wire Mesh with Perforated Metal

Sintered wire mesh with perforated metal is a certain laminate made by taking several layers of woven wire mesh and sintering them to a layer of perforated metal. The woven wire mesh layers consist of a filter layer, a protective layer, and in some cases a buffer layer between the fine mesh layer and the perforated plate. The perforated plate is then added as the base and the entire structure is sintered together to form a very strong yet tractable plate.

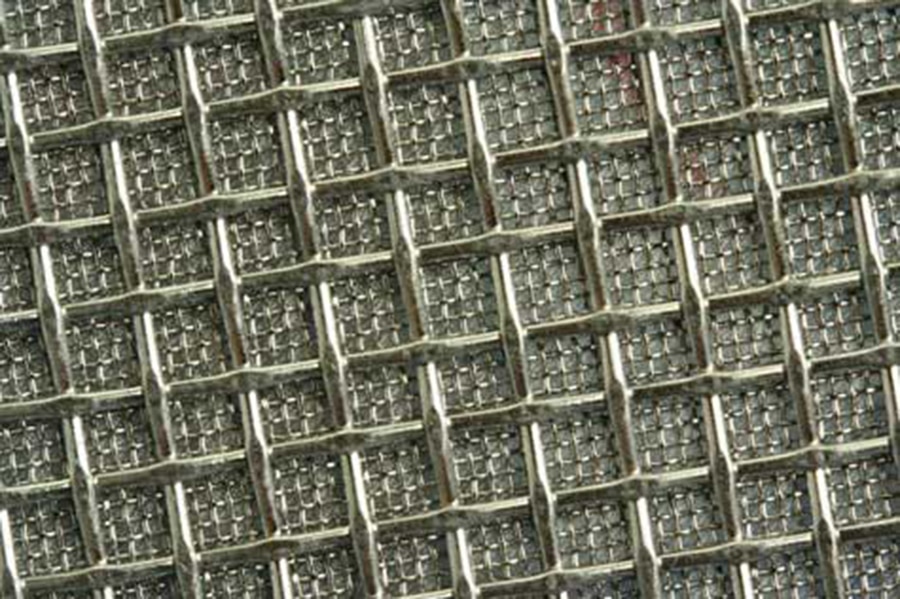

Sintered Square Weave Mesh

Sintered square weave mesh is made by sintering multiple layers of plain weave square woven wire mesh together. Because of the large open area percentages of the square woven wire mesh layers, this type of sintered wire mesh laminate has good permeability characteristics and low resistance to flow. It can be designed with any number and combination of square plain weave wire mesh layers to achieve particular flow and filtration characteristics.

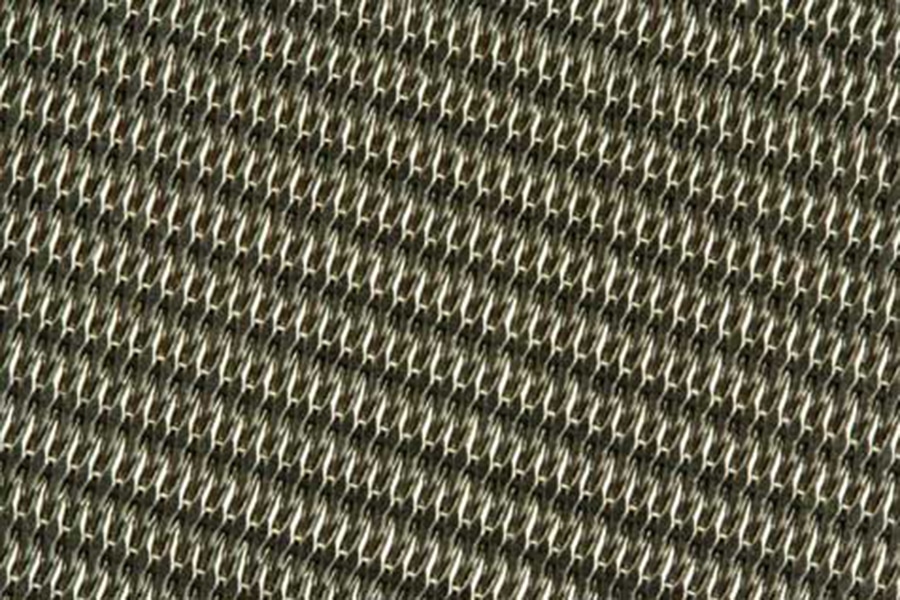

Sintered Dutch Weave Mesh

Sintered Dutch weave mesh is created by sintering two to three layers of plain Dutch woven wire mesh together. This type of stainless steel sintered wire mesh laminate has evenly spaced openings and good permeability to flow. It also has very good mechanical strength due to the heavy Dutch woven wire mesh layers. Sintered dutch weave mesh is commonly used in fluidized bed applications, and is useful for transporting powders and other dry solid materials.

HASTELLOY® C-22 Sintered Wire Mesh

HASTELLOY® C22 is a specialty industrial material with exceptional resistance to intergranular attack, pitting, and stress corrosion cracking. Its resistance level makes it an ideal choice for ballast water management, seawater filtration, pressure vessels, and applications including different types of chemical processes. Our HASTELLOY® C-22 sintered wire mesh comes in versatile 5-layer and 7-layer configurations in flat sheets up to 48”x48” size in various micron ratings.

904L Stainless Steel Sintered Wire Mesh

904L Stainless Steel is a type of non-magnetic stainless steel wire mesh with good weldability and formability. It has a high level of corrosion resistance and is commonly used in desalination plants, ballast water management systems on oceangoing vessels, and any filtration application where higher corrosion resistance than SS316L is required. Our SS904L sintered wire mesh filters come either in flat sheets or rolled and welded into cylindrical filters.

Our Common Sintered Wire Mesh Specifications

Sintered wire mesh products, with or without perforated metal, from Lawrence Sintered Metals, are manufactured in standard sheet sizes of 2’x4′, or 4’x4′. These sintered wire mesh laminates can be custom-made to meet a thickness requirement, a filtration rating, and/or a certain number of layers. If you have your own custom design, we can sinter just about any combination of wire mesh layers together to form a sintered mesh part.

These can be shipped as flat sheets, or we can cut a variety of custom-sized discs or donuts, or cut different-sized square and rectangular sheets. These sintered wire mesh laminates can also be rolled into tubes to form cylindrical sintered filters. We specialize in helping through the entirety of the ordering process, from initial design to the finished product, from sourcing the wire mesh to sintering the multiple layers to forming and fabricating into the final assembly.

Can you Sinter Together Multiple Layers of Wire Mesh?

In short, yes! Laminating multiple layers of woven wire mesh together is a more common application of the sintering process, which compared to a single layer of wire mesh, has increased mechanical strength, greater preservation of filter rating under pressure, is easier to clean, and has better structural integrity. A multiple-layer sintered wire mesh part can maintain the filtration rating of its finest mesh layer, while also maintaining the mechanical strength of its coarser support layers.

Common applications of sintering multiple layers of wire mesh together include:

- Liquid and gas filtration

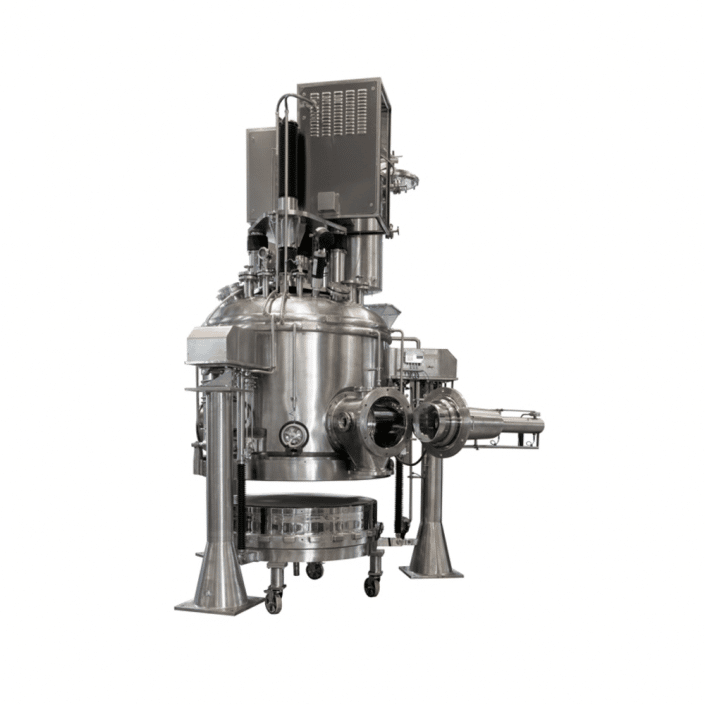

- Nutsche filters

- Fluidized beds

- Chromatography frits

- Centrifuges

- Hydraulic filters

- Sand control screens in oil wells

- Polymer filtration