Our customers use our wire mesh products in all sorts of ways, from protecting gardens from pests to keeping dangerous animals contained, and even adding a unique design element to interiors and exteriors. One of the most popular uses for wire mesh, however, is for filtration.

Many industries rely on filtration systems in order to manufacture goods, promote safety, and keep critical systems up and running. What are some of the ways wire mesh can be used in filtration? Let’s take a look at some examples.

Air Filtration

Many pollutants in the air can cause health issues, including excess amounts of pollen, dust, fibers, impurities, and even insects. We can create extremely fine wire mesh that can help block these air pollutants. Our mesh can be used in ventilation systems, air purifier materials, or in manufacturing plants where particulates in the air can be a significant concern.

Sand Screens

Purity of product is extremely important in many industries, especially for gas and oil companies. Since oil comes from the ground, good filtration systems are critical to ensure a higher quality product. Wire mesh can be used to screen out sand and other organic matter that can dilute oil. It can also be used to create drainage screen cartridges.

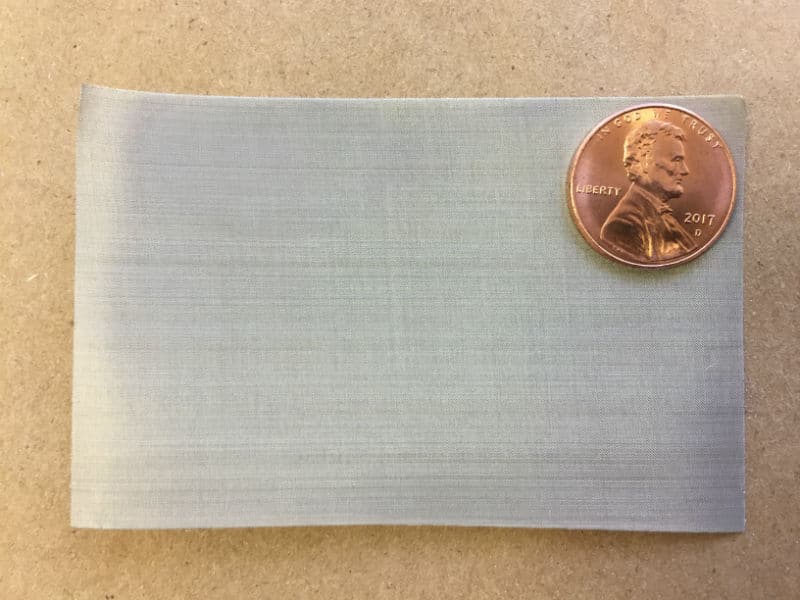

Micro Mesh Filters

Sometimes, filtration needs are very small, but that doesn’t mean they aren’t important! Many small products, including miniature valves and condensers and micro-electronics need filtration. This type of filtration requires extremely fine filters that are cut and shaped to perfection so that they can fit properly and perform the job.

Hot Gas Filtration

Many alternative fuels incorporate high temperature processing and thus require filtration. In particular, hot gas filtration requires metal filters that can stand up to punishing temperatures and maintain filtration integrity. Hot gas filtration is widely used in the processing of biofuels, as well as for spark arresting screens and power generation.

These are only a few examples of the many filtration applications that require wire metal mesh. If filtration is part of your company’s process, consider working with Lawrence Sintered Metals. We are happy to work with you to determine the ideal filtration medium to provide you with the best results possible. We may also be able to create custom wire mesh filtration for your project.