Lawrence Sintered Metals is here to help you understand the manufacturing process of Expanded Metal, Perforated Metal, and Wire Mesh.

A sheet of expanded metal is made by first creating multiple slits in the sheet, and then stretching the sheet of metal. When the metal is stretched it creates a unique diamond pattern opening with one of the strands protruding at a slight angle. The strands that are raised can be flattened later in the process if desired. There really is no waste during this manufacturing, which helps to keep the production costs low and it can add structural strength to the product.

A perforated metal sheet is a product that is made from sheet steel, which is then fed through a machine that punches out round holes or other designs depending on the customer’s needs. The holes can be placed in straight rows or staggered to help increase the amount of the openings. Usually the perimeter of the sheet has a boundary where holes are not punched; by doing this it adds stability to the sheet. The removed metal from the holes can be recycled but it also increases the cost of the product. The larger the hole size (or increased number of holes), the greater scrap volume, and therefore it can cause increased costs.

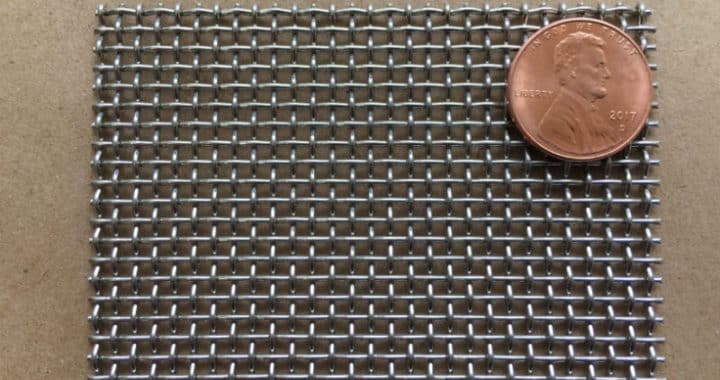

Our welded wire mesh is a metal wire screen that is made from various alloys including steel, stainless steel, brass and copper. Welded wire meshes have the wires welded together at all intersections for strength, flexibility, and a consistent opening size. Stainless steel welded mesh is used when rust and corrosion resistance is more critical. It’s also brighter and cleaner and can be used in a variety of visual applications. Our welded wire mesh is available in stainless steel, galvanized steel, or plain steel. Opening sizes range from a 1/4″ to 6″, and a variety of gauges or wire diameters are available in each type of alloy.

Also available in steel, stainless steel, brass and copper, woven wire mesh is made as a cloth with wire threads woven at right angles. Wires which run lengthwise are known as warp wires, whilst those running perpendicular are weft wires. Different weave styles are available, including plain weave which has every wire going over and under every other wire, and twilled weave where the wires cross two over and two under. We offer a variety of Dutch weaves as well. It can be made from various alloys including stainless steel, brass and copper. Wire cloth can be woven to create a variety of opening sizes and wire diameters.