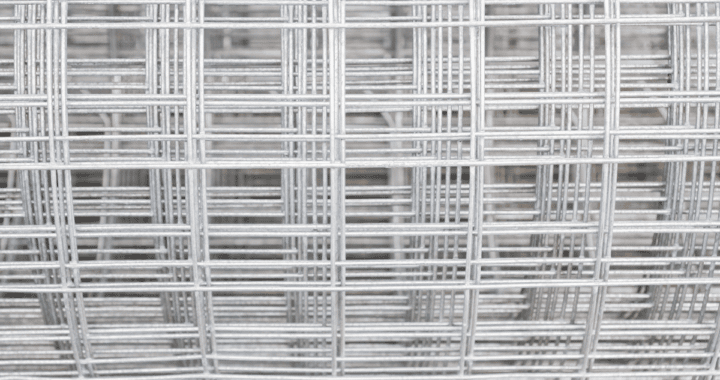

Welded Wire Mesh

Popular for a variety of commercial and industrial applications, welded wire mesh is a sheet of metal wires arranged into a stable grid pattern, then welded at the intersections for durability. Welded wire mesh is cost-effective and highly customizable, with options for a range of materials, thicknesses, and grid patterns.

Welded vs. Woven Wire Mesh

One of the main considerations in selecting a wire mesh is whether to select a woven or welded pattern. Woven mesh is more common overall because not all wires are suitable for welding. Some common wire metals, such as copper, can’t be welded, and others are too thin. In these cases, as well as when an extremely fine grid is desired, we weave the mesh together on a loom. For slightly heavier wires, we employ a crimping technique before feeding the wires into the loom. Pre-crimping the wires stabilizes the final mesh without the need for welding.

Even with crimping, woven mesh is not typically as strong as welded wire mesh, which remains rigid even with large openings in the grid pattern. Though not all metal wires can be welded, several popular options offer both durability and an aesthetically pleasing finish. T-304 stainless steel, T-316 stainless steel, plain (or carbon) steel, and galvanized before (pre-galvanized) steel are among the most common.

Wire Mesh vs. Wire Cloth vs. Hardware Cloth

Lawrence Sintered Metals manufactures wire mesh from three primary materials: galvanized steel, stainless steel, and plain steel. Galvanized and stainless steels offer protection against rust and corrosion, while plain steel tends to be more cost-effective. Plain steel is a highly durable material, so long as it is protected from certain environmental influences. If you aren’t sure about which one is the best option for your application, a member of our staff will be happy to assist you.

Stainless Steel Welded Wire Mesh

Stainless steel welded wire mesh offers the highest performance, valued for its strength and corrosion resistance. To achieve stainless steel’s attractive resistance properties, plain steel is mixed with chromium to yield a durable material that resists rusting. The primary tradeoff is that stainless steel is slightly more expensive than galvanized steel, which offers similar properties.

Primary applications for stainless steel wire mesh include those where the metal may be exposed to moisture or the elements or those that require a great deal of strength. Cases that justify the use of stainless steel mesh tend to be industrial applications that expose the mesh to greater demands. In less demanding environments, galvanized steel may be the more cost-effective solution. However, stainless steel is sometimes preferred for its clean, modern appearance, even when corrosion resistance is less of a concern.

Applications that may call for stainless steel mesh for either functional or aesthetic purposes include:

- Filters for chemical and oil processing

- Air filtration

- Food service and medical filters and guards

- Building facades

Galvanized Hardware Cloth

Galvanized steel, in contrast to stainless steel, gains its corrosion resistance through the application of a protective zinc coating. Since zinc decays far more slowly than steel, this coating allows the base metal to withstand a greater degree of environmental exposure than plain steel. Galvanized mesh is less expensive than stainless steel mesh, but it is still suitable for most of the same applications, making it a popular option when cost is a significant concern. Common uses of galvanized steel include:

- Home foundations

- Plumbing fixtures

- Agricultural fencing

Plain Steel Wire Mesh

Plain steel is the most affordable option, but it degrades more quickly than other options, so it is more likely to be used as a temporary option if environmental exposures are a concern. It may also be used in interior applications, for which moisture is less of a concern, or it may be coated in paint, as is often the case with infill panels. Of the three, plain steel is often the best choice for decorative applications due to its lower price. Other uses include:

- Fencing, especially indoors

- Shelving

- Temporary outdoor pens and enclosures

- Railings and dividers

Welded Wire Mesh Panels

Lawrence Sintered Metal provides high-quality plain, galvanized, and stainless steel wire mesh panels ideal for easy installation into virtually any project. Although wire mesh is often offered in rolls, panels offer maximum convenience as they are pre-cut and designed for ease of use. A variety of trim options are available to further customize your solution to your needs.

Our wire mesh panels are excellent choices for any of the following applications:

- Industrial, commercial, and residential fences, gates, or window screens

- Aesthetic details on building facades

- Machine guards for industrial machinery

- Heavy product storage

- Partitions

- Support for piping within the walls and ceilings of a structure

- Garden protection from insects and pestilent animals

- Agricultural barriers, panels, and fencing

- Infill panels for partitions, railings, and divider walls

Since wire mesh is both attractive and functional, it’s often integrated into projects ranging from residential to industrial. We can help you select the most appropriate metal, thickness, and size for your project, and we can discuss trim and finishing options.

Contact Lawrence Sintered Metals for Your Welded Wire Mesh Needs

Lawrence Sintered Metals, Inc. has been a reliable welded wire mesh manufacturer for more than three decades. In that time, we’ve gained expertise in galvanized, stainless, and plain steel meshes, as well as their uses across a diverse set of industries.

Our customers run the gamut from large, Fortune-500 businesses to long-time local patrons, and we strive to provide the same level of service to all clients. This commitment includes not only quality products but also reliable customer service, quick turnaround, and competitive pricing.

Our clients come to us from construction, architecture, oil & gas, pharmaceuticals, OEMs, aerospace, defense, industrial, agriculture, automobile, fields, among others, so we are familiar with the various constraints and challenges that different industries present.

To learn more about how we can adapt our offerings to suit your application, get in touch with Lawrence Sintered Metals today.

Specifications

| Mesh | Wire Diameter | Opening | Open Area Percentage | Weight per sq.ft |

|---|---|---|---|---|

| 2″ x 2″ | .063″ | 1.937″ | 93.8 | 0.134 |

| .080″ | 1.920″ | 92.2 | 0.216 | |

| 1 x 1 | .063″ | .937″ | 87.8 | 0.255 |

| .080″ | .920″ | 84.6 | 0.411 | |

| 2 x 2 | .047″ | .453″ | 81.2 | 0.284 |

| .063″ | .437″ | 76.4 | 0.512 | |

| 3 x 3 | .047″ | .286″ | 73.6 | 0.428 |

| 4 x 4 | .028″ | .222″ | 78.9 | 0.202 |

| .032″ | .218″ | 76.0 | 0.264 | |

| .047″ | .203″ | 65.9 | 0.576 |